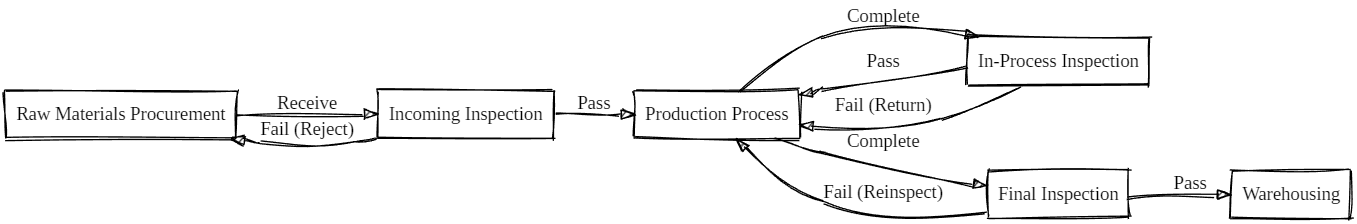

QC Flowchart and Advanced Testing Technologies

In the competitive world of fastener manufacturing, ensuring the quality and reliability of our products is paramount. That’s why we invest in cutting-edge testing equipment to guarantee precision and excellence in every fastener we produce. Let’s delve into the capabilities of each of our advanced testing devices:

Optical Screening Instrument

This instrument allows us to examine fastener surfaces with high resolution and accuracy, ensuring any imperfections or irregularities are detected and addressed promptly.

Salt Mist Test Machine

Our salt mist test machine simulates harsh environmental conditions to assess the corrosion resistance of our fasteners, ensuring they can withstand the rigors of real-world applications.

Three coordinates

Three coordinates

With precise measurement capabilities, our three-coordinate measuring machine ensures dimensional accuracy and consistency in our fastener production process.

Spectral analyzer

Spectral analyzer

This device analyzes the chemical composition of materials used in our fasteners, ensuring they meet the required standards for strength, durability, and corrosion resistance.

Bolt Detection

Bolt Detection

Our bolt detection system utilizes advanced technology to identify any defects or abnormalities in the bolts, ensuring only flawless products reach our customers.

Pull machine

The pull machine measures the tensile strength of our fasteners, ensuring they meet or exceed industry standards for strength and reliability.

Rockwell hardness tester

Rockwell hardness tester

This tester assesses the hardness of our fasteners, ensuring they have the necessary strength and durability for their intended applications.

Thread Friction coefficient testing machine

By measuring the friction coefficient of threaded fasteners, this machine ensures smooth assembly and secure fastening in real-world conditions.

Metallurgical microscope

With high magnification capabilities, our metallurgical microscope allows us to inspect the microstructure of our fasteners, ensuring they meet the required metallurgical standards.

Altimeter

This device measures the height of our fasteners with precision, ensuring uniformity and consistency in our manufacturing process.

Profilometer

Our profilometer measures surface roughness, ensuring the smoothness and quality of our fastener surfaces.