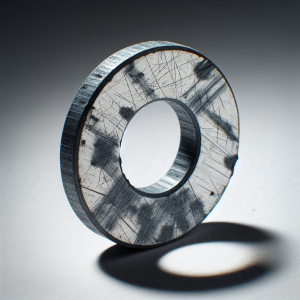

Why do flat washers deform easily during assembly, affecting fastening integrity? Let’s uncover the reasons behind this phenomenon and explore effective prevention methods.

What causes flat washers to deform? Flat washers are often subjected to high pressure and stress during assembly, leading to plastic deformation, especially when excessive torque is applied during tightening.

How does deformation affect fastening integrity? Deformed flat washers may lose their ability to evenly distribute the load and maintain proper tension, resulting in uneven clamping force and potential loosening of connections over time.

What measures can be taken to prevent deformation? Firstly, selecting high-quality flat washers made from durable materials can reduce the risk of deformation. Secondly, controlling the tightening torque to within the specified range can prevent excessive stress on the washers. Additionally, using lubricants or anti-seize compounds during assembly can reduce friction and minimize the risk of deformation.

By understanding the factors that contribute to flat washer deformation and implementing preventive measures, we can ensure the integrity and reliability of connections in various applications.

Remember, the next time you assemble components with flat washers, consider the importance of proper installation techniques and material selection to prevent deformation and ensure secure connections.